PVAc and EPI adhesives

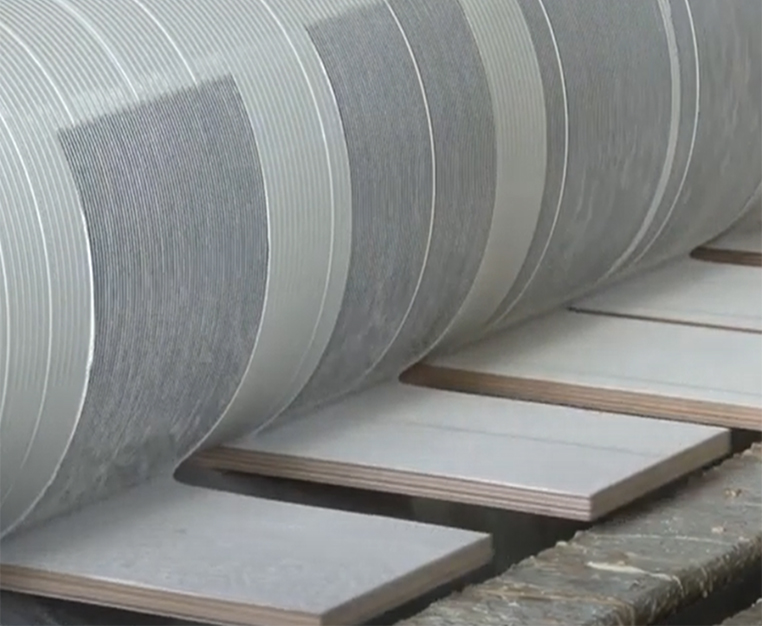

PVAc – polyvinyl acetate dispersion adhesive – is the most applicable adhesive in production, used in different gluing applications such as doors, parquet production, veneering, gluing details of solid wood, assembly operations, etc.

The PVAc adhesive that we offer can be classified D2, D3, D4 (standard EN 204/205) and XT6 or XT7 (standard EN 17619) durability class. Some adhesives have moderate resistance to high temperatures and meet the EN 14257 (WATT 91) standard.

EPI – polymer isocyanate emulsion adhesive – similar in appearance to PVAc adhesive, but the characteristics of EPI are several times better than PVAc. They are usually used for gluing window scantlings, double-layer parquet or house balk. The EPI glue line corresponds to durability class D4 according to standard EN 204/205 and EN 14257 ( WATT 91 ) with a large margin and corresponds to durability class C4 according to standard EN 12765. We have EPI adhesives approved and certified for gluing load-bearing constructions.